Countertops are one of the most used surfaces in both residential and commercial spaces. Their installation requires detailed planning to achieve a perfect fit, proper support, and alignment with other design elements.

A minor miscalculation in dimensions, material specifications, or cutouts can lead to costly delays, wasted materials, or even structural issues. This is where countertop shop drawings play a critical role.

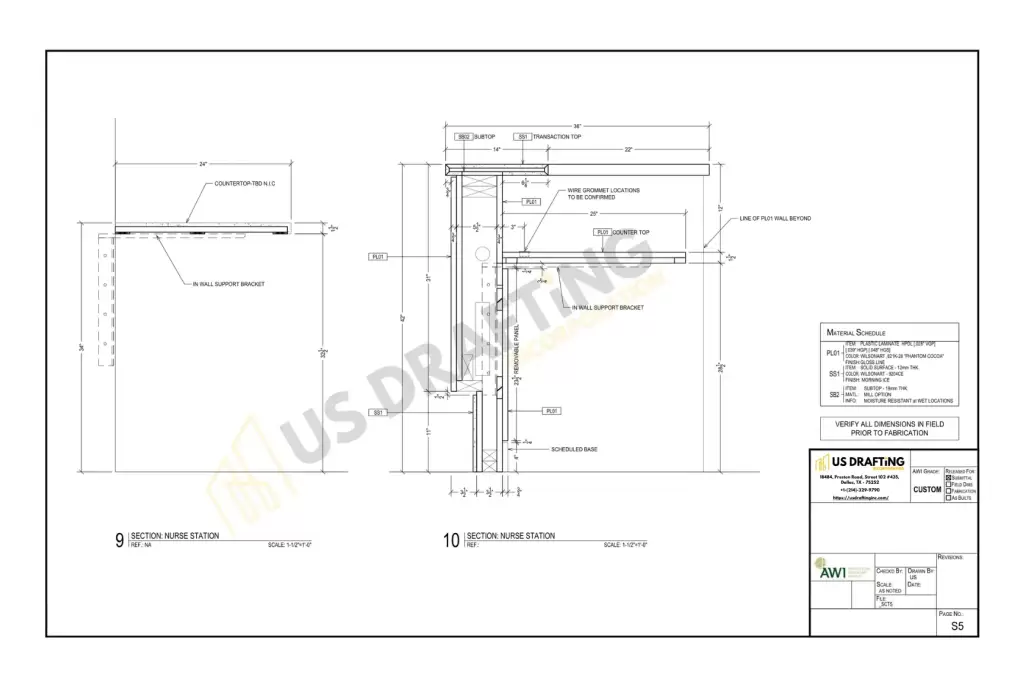

These drawings are detailed technical documents that provide accurate measurements, material specifications, edge profiles, cutouts for sinks and appliances, and other fabrication details. They guide fabricators and installers, helping them match the final product to the design intent and actual site conditions.

Without proper shop drawings, errors are almost inevitable. A great example can be seen in a real case shared on Reddit, where a homeowner faced a frustrating situation after a wrongly installed countertop. The sink was off-center, the cutouts didn’t match, and now they’re stuck between costly rework or compromising on quality.

This type of issue is more common than it should be and often, it stems from a lack of clear, detailed planning documents. This guide will break down the elements of countertop shop drawings, explain the process of creating them, and explore how they contribute to a smooth and accurate installation.

Key Elements Of Countertop Shop Drawings

It contains several technical details that guide fabrication and installation. Each element is important for maintaining accuracy and preventing errors during manufacturing and assembly. Below are the key components found in these drawings:

Dimensions & Layout

- The drawings provide accurate measurements of the countertop, including total length, width, and depth.

- Layout details show how the countertop sections fit within the overall space, including corner joints, seams, and connections to adjacent surfaces.

- Information on backsplashes, overhangs, and support requirements is included to avoid misalignment during installation.

Material Specifications

- The type of material (e.g., granite, quartz, marble, laminate) is clearly noted.

- Thickness specifications provide that the selected material meets structural and design requirements.

- Finish details such as polished, honed, or textured surfaces are indicated based on project needs.

Edge Profiles & Finishes

- The shop drawings define the edge profile for the exposed sides of the countertop, such as straight, beveled, bullnose, or ogee edges.

- Edge treatments impact both aesthetics and functionality, so precise labeling is necessary for fabricators.

- Any custom edge designs or laminated edges for extra thickness are also included.

Sink & Appliance Cutouts

- Cutout locations for sinks, cooktops, and other built-in appliances are marked with exact dimensions.

- The type of sink (under-mount, drop-in, or integrated) is specified, as it affects fabrication methods.

- Tolerances for cutouts are included to prevent errors that could lead to improper fitting.

Backsplash & Overhang Details

- If a backsplash is included, its height, thickness, and attachment method are detailed.

- Overhang specifications indicate how far the countertop extends beyond the cabinetry or support base.

- In cases where additional support is required for extended overhangs, the drawings include bracket placements or corbel requirements.

How We Create Countertop Shop Drawings?

Our process for creating countertop shop drawings is built on accuracy, clarity, and real-world practicality. Here’s how we approach each step:

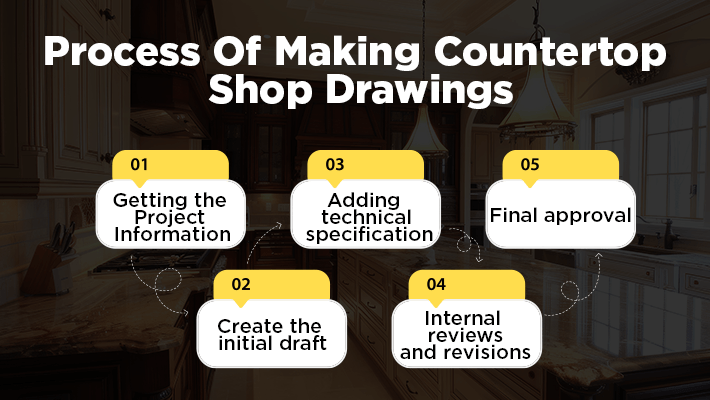

1. Getting the Project Information ready

We start by collecting all essential details such as architectural plans, selected materials, and precise site measurements. If the project involves a renovation, we pay close attention to existing conditions like wall angles, cabinet alignment, and appliance locations.

Even small discrepancies at this stage can cause major installation issues, so we double-check everything to avoid surprises later.

2. Creating the Initial Draft

Using advanced CAD software such as AutoCAD, our team prepares a scaled layout of the countertop. This includes overall dimensions, material thickness, sink and appliance cutouts, and edge profiles. We include top views, front elevations, and sections to give fabricators and installers a complete and clear reference.

3. Adding Technical Specifications

Once the layout is ready, we add key technical details. These may include backsplash height, overhang dimensions, and notes on required supports for cantilevered sections. We also plan out seam locations based on material limits and installation logistics. Every sink and cooktop cutout is positioned with precision to avoid errors during fabrication.

4. Internal Review and Revisions

Before anything is finalized, our team runs a detailed review to check for accuracy and alignment with the project’s design intent. If there are updates from architects or contractors, we incorporate them and make the necessary adjustments. This review step helps prevent costly revisions once fabrication has started.

5. Final Approval and Fabrication Support

After approval, we provide the final shop drawings to the fabrication team. These drawings act as a roadmap for cutting, shaping, and finishing the material. When the countertop sections are delivered to the site, our drawings continue to guide the installation, helping the team place and secure everything exactly as intended.

How To Get Started With Countertop Shop Drawings?

Starting your countertop shop drawings is easier than you might think as long as you have the right information ready. Whether you’re working on a new build or a renovation, the key is to share clear project details from the beginning. This helps us create drawings that match the site perfectly and avoid issues down the line.

Here’s what we typically need before getting started:

- Project Plans or Layouts: These can be architectural drawings, cabinet layouts, or even hand sketches that show where the countertop will go.

- Accurate Measurements: We’ll need site measurements especially wall lengths, cabinet dimensions, and space for appliances. If it’s a renovation, we’ll also look at how existing elements line up.

- Material Selection: Let us know what type of countertop material you’re using (quartz, granite, laminate, etc.). Different materials may require different cutout allowances or support details.

- Appliance and Sink Specifications: Exact model numbers or cutout templates help us place openings correctly, so there are no surprises during installation.

Once we have this information, we begin drafting. You’ll receive a detailed shop drawing showing all dimensions, cutouts, edge details, and anything else needed for fabrication. If adjustments are needed, we’ll update the drawings and send them for final approval.

At US Drafting Inc., we work closely with fabricators, contractors, and designers to make sure every detail is right before the countertop gets cut. If you’re ready to start or have questions, just reach out, we’re here to help make the process smooth and accurate.