Every stunning piece of custom woodwork you see, whether a cabinet, a wall panel, or moldings, starts with a carefully crafted plan. These plans, known as millwork shop drawings, are the backbone of any woodworking project.

At US Drafting Inc., creating these drawings isn’t just about putting lines on paper; it’s about translating a vision into precise, actionable details. The client often has a brilliant design idea, but when it’s time to build, things don’t align, dimensions are off, and materials don’t match. That’s where millwork shop drawings make all the difference.

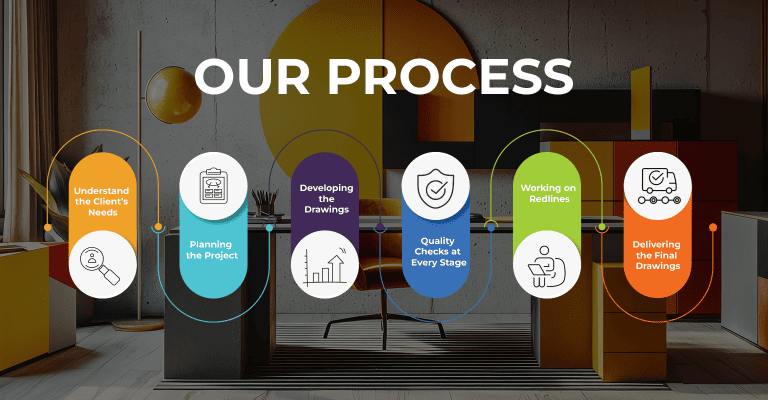

Today I’ll take you behind the scenes of how we create these drawings. We start with gathering design details to drafting, revising, and finalizing, I’ll explain to you the step-by-step process that guarantees precision and quality.

Step-by-step Process For Preparing Millwork Shop Drawings

Our process of preparing millwork shop drawings involves several steps. Let me explain every step in detail.

Understand the Client’s Needs

Once the client shares their project details, we begin by asking for any past work samples. These samples help us understand their preferences, style, and overall expectations.

Additionally, we request the CTB (Color Table) file to maintain consistency in the drawing’s appearance, such as line weights and colors. This step helps us align with the client’s vision immediately.

Planning the Project

After gathering all necessary inputs, our team dives into the planning phase. This is where we analyze the project scope, break it into manageable parts, and decide the best way to approach the drawing.

The planning phase is crucial because it sets the foundation for accuracy and efficiency throughout the process.

Developing the Drawings

With a clear plan in place, we begin drafting the millwork shop drawings. Using advanced CAD software, our team carefully details every aspect of the project, including dimensions, materials, joinery, and finishes. Each drawing is crafted to provide clear instructions for fabrication and installation.

Quality Checks at Every Stage

To maintain high standards, our process goes through three levels of quality checks:

- Level 1: Internal Review – The drafting team reviews their work to make sure all basic details are covered.

- Level 2: Peer Review – Another expert from our team reviews the drawings for technical accuracy and completeness.

- Level 3: Final Check – A senior reviewer gives the drawings a final look to confirm they are ready for delivery.

Working on Redlines

If the client provides feedback or requests changes, we incorporate those into the drawings. Our team carefully reviews and addresses redlines to make sure the final product matches the client’s expectations. This step is critical in refining the drawings and addressing any potential gaps.

Delivering the Final Drawings

Once the drawings pass all quality checks, we share them with the client. The final product is precise, detailed, and tailored to the client’s requirements, ready to be used for manufacturing or installation.

Software We Use For Millwork Shop Drawings

At US Drafting Inc., we rely on advanced software to deliver accurate and high-quality millwork shop drawings. While we don’t use all of them for every project, the choice of software depends on the project’s requirements and client preferences.

Here’s a quick look at the software we use and their purpose:

AutoCAD

AutoCAD is widely recognized for its precision and versatility in 2D drafting. We use AutoCAD to create detailed plans, elevations, and section views that lay out the foundation of any millwork project.

Its extensive library of tools and customization options helps us draft layouts that communicate dimensions, materials, and assembly details. AutoCAD is a dependable choice for projects requiring straightforward, accurate 2D drawings.

Bluebeam

Bluebeam is an excellent tool for managing drawing reviews and feedback. We use it to add comments, markups, and redlines on PDF drawings. This helps smoothen the communication process with clients and collaborators.

Bluebeam also makes it easier to organize and share files, keeping all project details accessible and up-to-date. It’s especially helpful during the revision process, allowing us to stay on track and address any updates efficiently.

Cabinet Vision

When projects involve custom cabinetry, Cabinet Vision becomes essential. This software specializes in designing cabinets with incredible detail, including internal components, hardware, and finishes.

It allows us to visualize designs in 3D, helping clients better understand how the final product will look. Cabinet Vision also generates shop-ready drawings and cut lists, making it easier for manufacturers to produce cabinets exactly as planned.

Revit

Revit is a powerful tool for projects requiring advanced 3D modeling and coordination. It helps us create detailed parametric models that represent millwork in three dimensions.

Revit is particularly useful for larger or more complex projects, where coordination with other design disciplines like architecture or structural engineering is necessary. With Revit, we can identify potential clashes and make adjustments early, saving time and reducing errors during production or installation.

Why To Consider US Drafting Inc. For Your Next Millwork Project?

Millwork shop drawings are the foundation of any woodworking project. They give clear instructions for making and installing custom woodwork. We focus on creating high-quality drawings that make projects easier and more efficient.

Our team works on a variety of millwork projects, from cabinetry to detailed woodwork. We use advanced software like AutoCAD for precise 2D plans, Cabinet Vision for custom cabinet designs, Revit for 3D models, and Bluebeam to handle feedback and revisions. This helps us choose the right tools based on what each project needs.

We work closely with our clients to understand their ideas and preferences. By reviewing past work samples and addressing redlines, we make sure our drawings meet expectations. Every drawing goes through three levels of quality checks to catch mistakes and avoid delays during production or installation. Let’s start your project today with US Drafting Inc.!

2 Comments