Whenever I see workers struggling to install a massive stone on a wall, tilting it slightly, adjusting it again, and stepping back to check the alignment, I immediately wonder if they have proper stone shop drawings. In most cases, when things don’t fit, it’s not the stone that’s the problem. It’s the lack of precise planning.

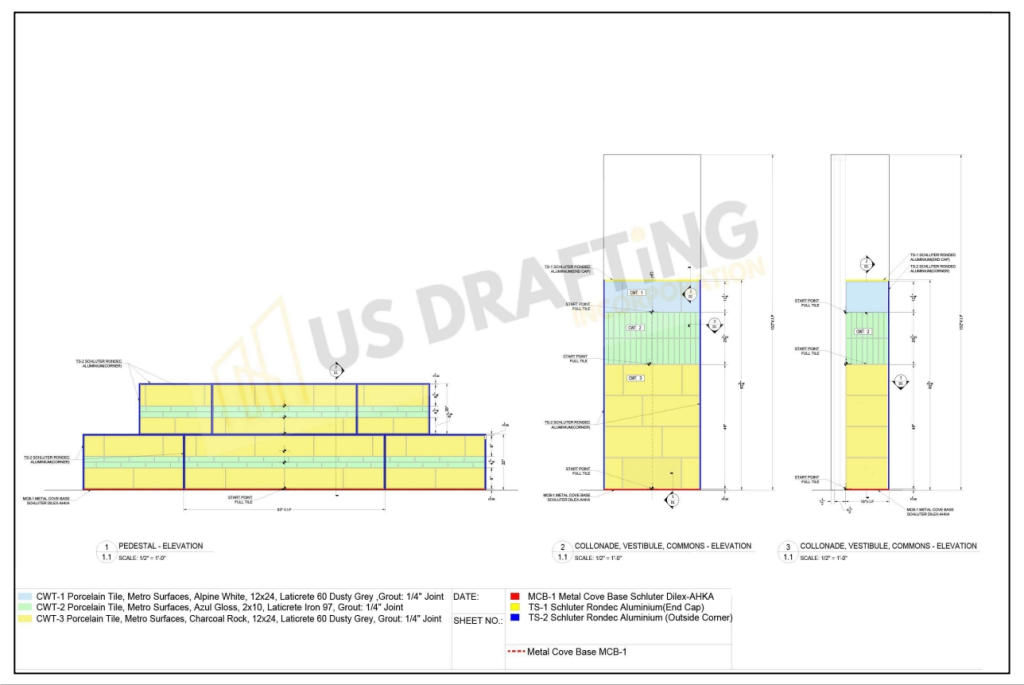

Stone shop drawings are the foundation of any successful stonework project. These detailed technical drawings include exact dimensions, edge profiles, material specifications, joint placements, and anchoring details. They serve as a blueprint for fabricators, contractors, and installers so that every piece is cut, shaped, and placed with accuracy.

Without these drawings, mistakes are common. Pieces might be too short, edges might not align, or mounting points might be off. This leads to costly rework, wasted materials, and frustrating delays. But with well-prepared stone shop drawings, everything is mapped out before a single cut is made, making the installation process smooth and error-free.

These drawings turn design concepts of luxury marble countertops, an intricate stone façade, or a grand staircase into reality. They bridge the gap between vision and execution. This makes sure that what is planned is exactly what gets built. Let’s discuss the stone shop drawings in this guide in more detail.

What Is Included In Stone Shop Drawings?

Stone shop drawings provide all the necessary details to cut and install each piece correctly. They help fabricators, and installers to avoid mistakes and delays. Here’s what they typically include:

- Exact Dimensions: The length, width, thickness, and any cutouts needed for fixtures or fittings. This is for precise cutting and a perfect fit.

- Edge Profiles and Finishes: It should include details on edge styles like beveled, bullnose, or mitered, along with the surface finish (polished, honed, flamed, etc.).

- Joint and Seam Placement: Markings that show where stone pieces will connect, helping to create seamless and strong installations.

- Anchoring and Fastening Details: Instructions on how the stone will be secured, whether on walls, floors, or countertops.

- Material Specifications: Information about the type of stone, finish, and any special treatments needed to match the project’s design and quality requirements.

Use-cases Of Stone Shop Drawings

Stone shop drawings are essential in many types of projects where accuracy and high-quality craftsmanship matter. There are many use cases for stone shop drawings, let’s discuss some of them:

1. Architectural Stone Cladding

These drawings are used for building exteriors, stone cladding enhances durability and aesthetics. Shop drawings show panel sizes, joint placements, and anchoring details to ensure proper alignment and structural integrity.

2. Countertops and Vanities

For kitchens, bathrooms, and commercial spaces, stone countertops require precise measurements, edge profiles, and cutout details for sinks and fixtures. These drawings prevent misfits and material waste.

3. Flooring and Paving

Large-scale stone flooring or patterned paving requires exact layouts to maintain symmetry and avoid irregular gaps. Shop drawings map out the tile sizes, joint spacing, and installation patterns.

4. Stairs and Treads

Stone staircases need careful planning so each step is uniform in size and properly secured. Drawings specify tread dimensions, riser heights, and edge details for both safety and aesthetics.

5. Fireplaces and Feature Walls

Intricate stone designs for fireplaces or decorative walls require precise cutting and alignment. Shop drawings provide a clear guide to achieving the desired texture and finish.

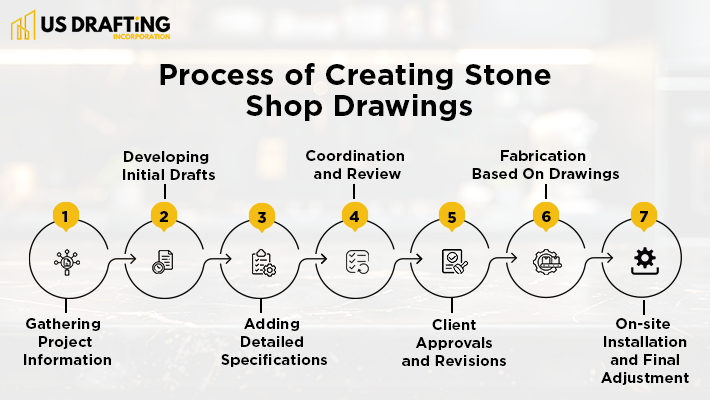

Step-by-Step Process of Stone Shop Drawings

The process of developing stone shop drawings is a detailed process that transforms design concepts into accurate fabrication and installation plans.

Every step plays a role in making sure the final result is both structurally sound and visually perfect. Here’s how the process unfolds:

1. Gathering Project Information

Everything starts with understanding the project. Architects, designers, or contractors provide initial plans, sketches, and specifications. This includes:

- The type of stone being used (marble, granite, limestone, etc.).

- Required dimensions, thickness, and finishes.

- Installation methods, anchoring systems, and structural requirements.

- Any special design features, patterns, or carvings.

At this stage, the focus is on collecting all the necessary details so the drawings align perfectly with the project’s needs.

2. Developing Initial Drafts

Once the information is gathered, drafters create the first set of drawings using CAD software. These initial drafts include:

- Basic layouts and dimensions.

- Placement of each stone piece.

- Edge profiles and cutout locations.

These drafts are reviewed internally to check for consistency and accuracy before moving forward.

3. Adding Detailed Specifications

After the basic layout is approved, the drawings are refined with more details, such as:

- Exact cutting dimensions for fabricators.

- Joint and seam placements for perfect alignment.

- Fastening and anchoring details for secure installation.

- Material callouts, surface finishes, and edge treatments.

This step reduces the risk of errors because every detail needed for fabrication and installation is defined.

4. Coordination and Review

Stone shop drawings must align with other construction elements, such as walls, floors, and structural supports. This phase involves coordinating with architects, engineers, and contractors to:

- Verify that stone elements fit correctly within the overall design.

- Resolve any potential conflicts with other materials or systems.

- Make adjustments before finalizing the drawings.

This step prevents installation issues and costly modifications later in the process.

5. Client Approval and Revisions

Now, the drawings are sent to the client for approval. This could be the project owner, architect, or someone related to the project. They review the plans and request any changes if needed.

- If revisions are required, adjustments are made, and the updated drawings are resubmitted.

- Once approved, the drawings move to the fabrication phase.

This step confirms that all expectations are met before cutting begins.

6. Fabrication Based on Drawings

With approved shop drawings in hand, fabricators cut and shape each stone piece according to the specifications. This phase requires accuracy, as even a small mistake can cause misalignment during installation.

- Stone pieces are cut using CNC machines or by skilled craftsmen.

- Edge profiles and surface finishes are applied.

- Quality checks make sure that all dimensions match the drawings.

At this stage, the accuracy of shop drawings directly affects the success of the project.

7. On-Site Installation and Final Adjustments

Once fabrication is complete, the stone pieces are transported to the site for installation. Installers use the shop drawings as a guide to:

- Position each piece correctly.

- Follow the planned joint and seam placements.

- Secure the stone using the specified anchoring methods.

Any minor adjustments, such as edge refinements or alignment corrections, are made on-site based on the shop drawings.

What to Look For In Stone Shop Drawings Services?

In short, Finding the right stone shop drawing service can make all the difference in how smoothly your project runs. A good service doesn’t just provide drawings; it gives you a clear, reliable plan that makes fabrication and installation easier. So, what should you look for?

- Clear and Precise Details: The best shop drawings eliminate confusion. Every measurement, cut, and placement should be well-defined.

- Industry Experience: Stone projects have unique challenges. Work with a team that understands stone fabrication and installation inside and out.

- Coordination: Good shop drawings fit into the bigger picture, aligning with architectural and structural plans for a hassle-free process.

- Timely Delivery: In construction, time is money. Late or inaccurate drawings can cause delays and costly mistakes.

At US Drafting Inc., we know how important precision is, not just for stone, but for all architectural details. That’s why we specialize in floor and tile shop drawings, helping contractors and designers bring their visions to life with accuracy and efficiency. If you’re looking for detailed, easy-to-follow shop drawings, let’s talk!

1 Comment